Arrived

Mast removed

Mastless for the first time in a long while.

Raw water intake thru-hull before. The red valve handle is broken.

Raw water thru-hull seacock removed.

Some general cleanup of the area.

G10/FR4 backing plate epoxied into place.

Fiberglass placed over drainage channel.

New paint over all.

All finished. New thru-hull, propeller shaft, driplesss seal and rebuilt sea strainer.

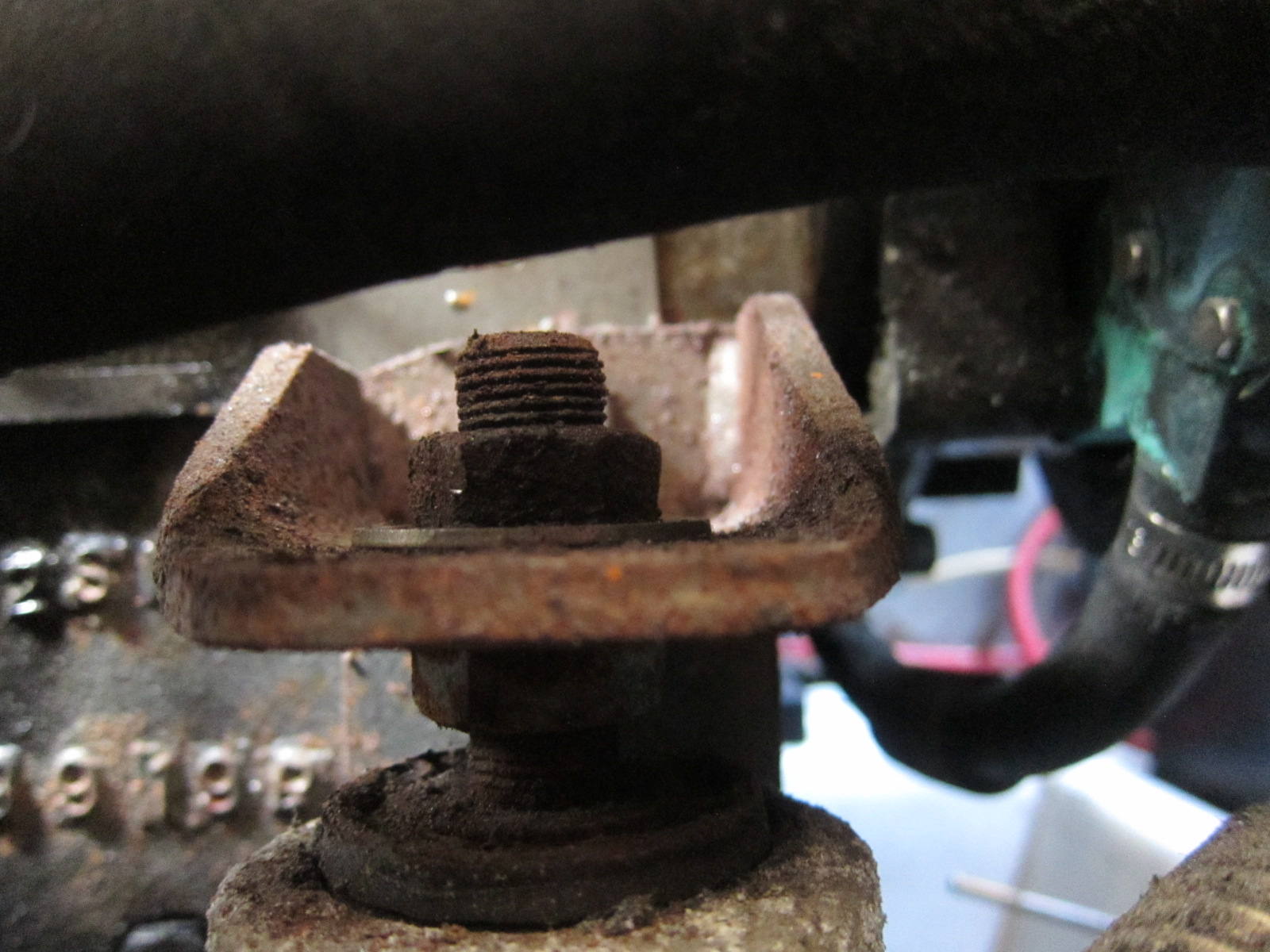

Corroded rudder 304 stainless steel packing nut.

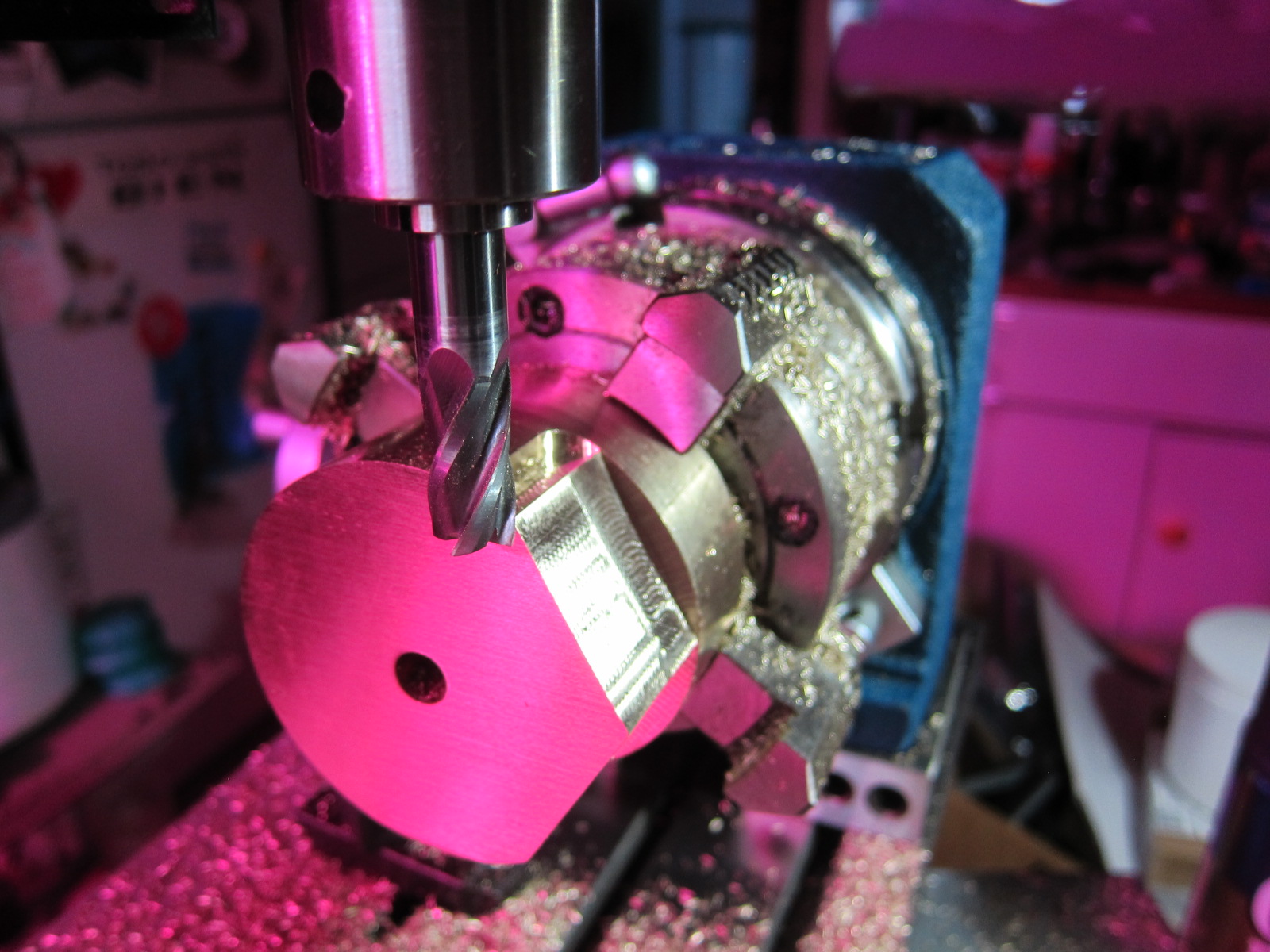

Using the mill to machine the hex part of the nut.

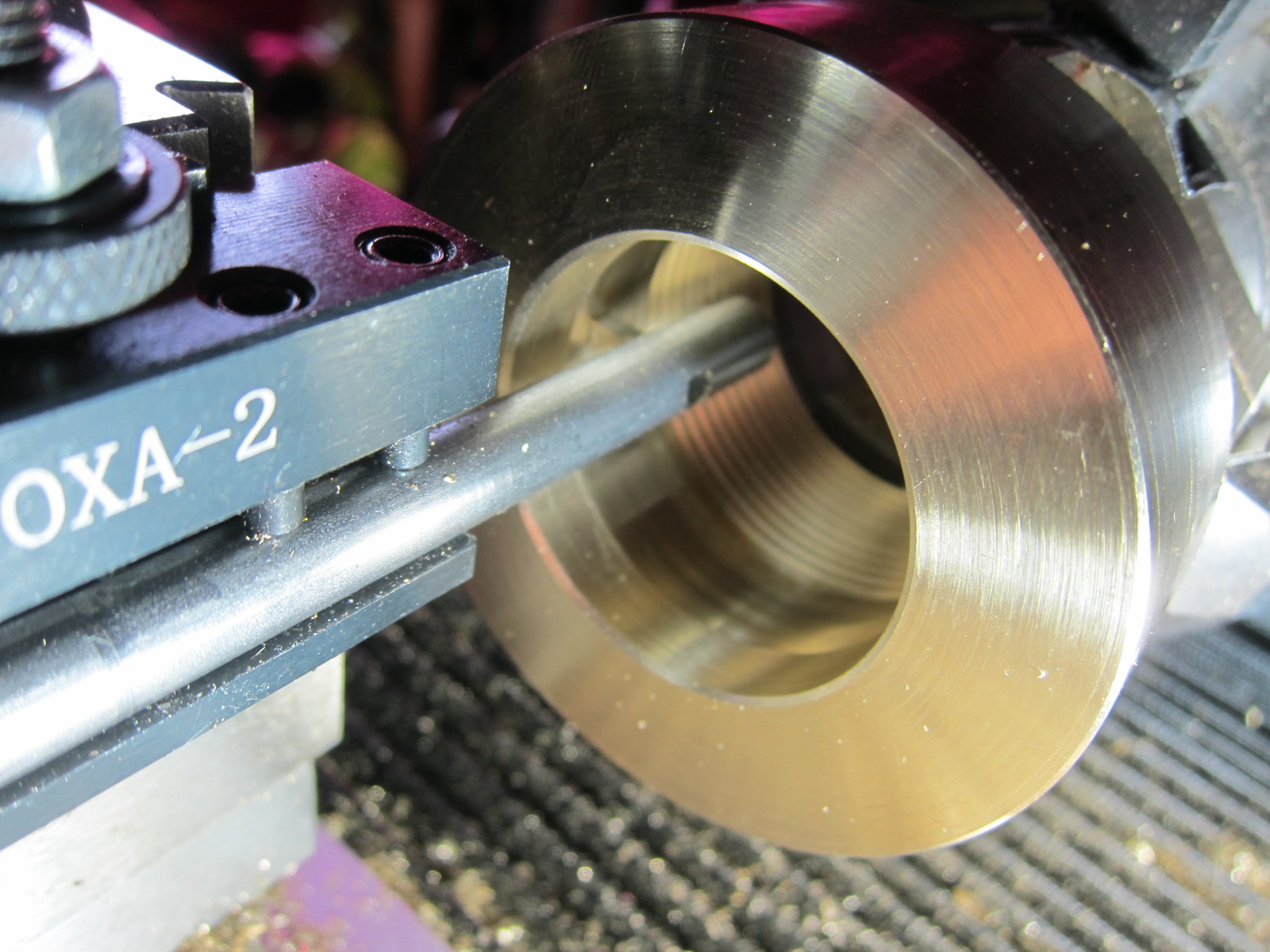

Using the lathe to cut the threads and hollow out the inside.

A new rudder packing nut was machined from nickel aluminum bronze.

Rudder steering system needs to come out to remove the rudder.

The bolts on the radial drive wheel are very stuck. It has to be cut out.

Comparing the new radial drive wheel to replace the stuck one.

The radial drive wheel is cut out. Now the rudder can be removed.

New and old radial drive wheels. Had to cut the old one out due to stuck bolts.

New drive wheel, rudder stops and cables installed.

Freshwater system before.

Replaced all the water lines.

Old hoses all cut out.

New fresh water system and removal of unused thru-hull.

It would appear that this boat had, at one time, either a single-side-band radio or a Loran-C global positioning system that required a hull ground plate. Grounding plates like this are not supposed to be painted but this one was. This plate was connected directly to the radar console unit inside the boat. The plate was removed and the screw holes filled with epoxy and backed inside with G10/FR4 discs.

Sintered bronze grounding plate screwed to the hull.

G10/FR4 discs epoxied over the screw holes inside the hull.

The state of the thru-hulls before work begins.

A much stronger thru-hull system.

All finished.

Been staring at this sketchy looking thru-hull. It has to go.

Ball valve removed. It looked closed but was actually half open.

Cleaning up area.

Removed gelcoat to expose fiberglass hull for epoxy.

A view from outside of hull.

All fiberglassed over. The hole is gone.

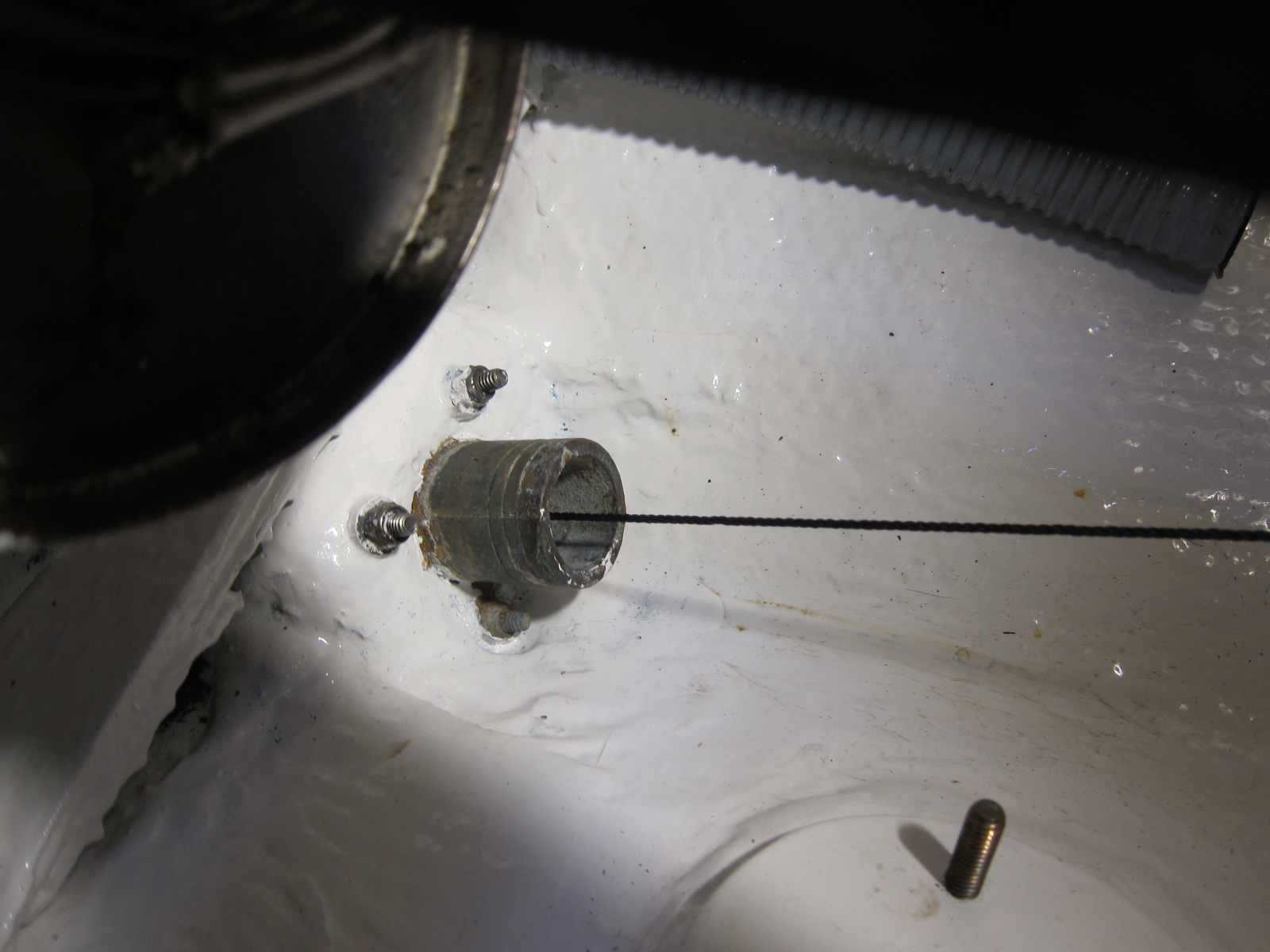

3D printed string flange attached to the motor.

The string exiting the boat through the stearn tube.

Using washers to get finer alignment.

Strut aligned using the string. Ready for expoxy shims.

Strut now shimmed in place with epoxy.

Shimmed strut looking down aligned string.

Old rusted motor mounts need replacing.

Some rusted bolts on motor mounts needed to be cut off.

New motor mounts ready for install.

Motor mounts installed.

Old crusty, non-functioning fuel level sender.

The sender top is full of tan granules of corrosion.

The new capacitive fuel sender that has no moving parts.

"The new capacitive fuel sender installed on the diesel tank.

Main blige area before.

A new coat of paint in the bilge.